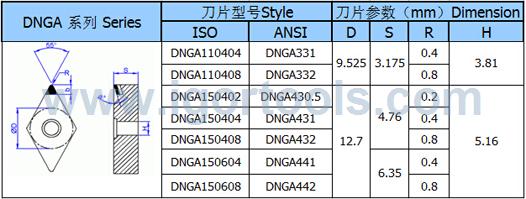

DNGA, DNGW150608 PCD turning insert

Applications:

Non-Ferrous Metals

- Aluminum

- Silicon-Aluminum Alloys

- Brass Alloys

- Bronze Alloys

- Copper

- Copper Alloys

- Lead Alloys

- Manganese Alloys

- Presintered Tungsten Carbide

Abrasive Nonmetallics

- Carbon

- Ceramics

- Fiberglass Composites

- Graphite

Advantages:

- Increased tool life

- Ability to cut a wide range of materials

- Resist chipping in interrupted cuts

- High material removal rates

- Reduced cycle time

- Improved part size control Common applications for PCD:

Abrasive Non-metallics

Carbon

Ceramics

Fiberglass Composites

Graphite

Plastics

Rubber

Nonferrous Metals

Aluminum

Aluminum Alloys

Brass Alloys

Bronze Alloys

Copper

Copper Alloys

Lead Alloys

Manganese Alloys

Metal Matrix Composites

Sintered Tungsten Carbide

Primary PCD Markets

Automotive

Transmission Housings and Valve Bodies; Manifolds; Cylinder Heads; Wheels; Pistons; Oil, Water, Power Steering and Fuel Pumps; Brake Cylinders; Carburetors; Engine Blocks; Alternator, Starter and Air Conditioning Housings

Pumps/Valves

Housings, Moving Parts

Home Appliances

Housings/Compressor Pistons

Aircraft/Aerospace

Cowling, Wing Tips, Ducts, Floor Posts, Structural Components, Trim Panels

Electrical Machinery

Commutator Shafts/Housings

Computer and Electronic

Moving Discs; Mirrors/Lenses

- Previous Product:TNGA160304 pcd tipped insert

- Next Product:PCD Insert,Diamond inserts,cbn inserts,diamond cbn inserts